| Availability: | |

|---|---|

| Quantity: | |

C140

HYTON

84749000

Mn18Cr2 Jaw Plate with High Chromium Alloy Insert Suit to Metso C140 Mobile Jaw Crusher Wear Parts

Product Description

Hyton produce High manganese casting liners mainly include Mantle, Bowl Liner, Feed Cone, jaw plate, check plate, Arm Liner, Steel Ball, and etc. Hyton’s casting wear parts can suit lots of world famous crushing equipment brand such as: Nordberg, Telsmith, Terex, Symons, Kleeman, Extec and etc.

Spare parts of Hyton mainly suit the cone crusher model under below

GP100S GP200S GP300S GP500S GP7

GP100 GP11F GP11M GP200 GP220 GP300 GP330 GP550

HP100 HP200 HP300 HP400 HP500 HP700 HP800 HP3 HP4 HP5 HP6

MP800 MP1000 MP1250 MP2500

CH420 CH430 CH440 CH660 CH830i CH840i CH860i CH865i CH870i CH890i CS420 CS430 CS440 CS660 CS840i

2ft , 3ft , 4ft, 4 1/4ft, 5 1/2ft, 7ft,

Terex: C-1540 C-1540R C-1545 C-1545P C-1550 C-1550P C-1554

Telsmith: T300 T400 T500 T900 36 S & FC 48 S & FC 52 S & FC 57 S & FC 66 S & FC 38 SBS 44 SBS 52 SBS 57 SBS 68 SBS

TP260 TP350 TP450 TP600 TP900

TC36 TC51 TC56 TC84 TC84X TP260 TP350 TP450 TP600 TP900

Spare parts of Hyton mainly suit the jaw crusher model under below

C80 C96 C100 C106 C116 C3054 C110 C120 C125 C130 C140 C145 C150 C160 C200

CJ211 CJ408 CJ409 CJ411 CJ412 CJ612 CJ613 CJ615 CJ815

JM806 JM907 JM1107 JM1108 JM1206 JM1208 JM1211 JM1312 JM1511 JM1513

Terex: J-1170 J-1175 J-1170AS J-1160 J-960 J-1480

Telsmith KPI-JCI(PIONEER): H2238 H2550 H3244 H3450 Tel2550 Tel3858 Tel4244 Tel5060 Tel5260

H2238/H2550/H3244/H3450,2240/2421/2430/3042/3646/3858/4240/4244,4250/ 5060,5260

CT1030 CT1040 CT1048 CT1252 CT2036 CT2436 CT3042 CT3254

CT3254B CT3648 CT4254 CT4763 CT6080

Cone Crusher Spare Parts-Cone Concave Advantage and Features

1. Use: Wear parts for crushers in the quarry, mining, cement, aggregate, recycling, shredding and demolition fields etc.

2. High manganese steel material specifications: Mn14Cr2, Mn18Cr2, Mn22Cr2.

3. High manganese steel hardness: HB180-220.

4. High manganese steel tensile strength: ≥685Mpa.

5. High chromium material specifiations: CBCr15. CBCr20. CBCr26.

6. High chromium hardness: CBCr15≥56HRC. CBCr20≥58HRC. CBCr26≥60HRC.

7. More than 20 years of experiences on casting and producing crushers.

8. Sophisticated processing equipment and completed inspection facility.

9. Strong wear resistance and long life span, can be used in harsh environment and serious abrasion.

| Material | C | Si | Mn | Cr | Mo | Ni | Cu | S | P |

| ZGMn14Cr2 | 0.9-1.3 | 0.3-1.0 | 11.0-14.0 | 1.5-2.5 | / | / | / | ≤0.04 | ≤0.06 |

| ZGMn18Cr2 | 1.1-1.5 | ≤0.8 | 16.5-19.0 | 1.5-2.5 | / | / | / | ≤0.04 | ≤0.07 |

| ZGMn22Cr2 | 1.1-1.4 | ≤0.8 | 20.0-22.0 | 1.5-2.5 | / | / | / | ≤0.04 | ≤0.07 |

| CBCr15 | 2.0-3.0 | <1.0 | 0.5-2.0 | 12.0-18.0 | 0.5-2.5 | 0-1.0 | 0-1.2 | <0.06 | <0.10 |

| CBCr20 | 2.0-3.0 | <1.0 | 0.5-2.0 | 18.0-23.0 | 0.5-2.5 | 0-1.5 | 0.8-1.2 | <0.06 | <0.10 |

| CBCr26 | 3.1-3.5 | 0.4-0.9 | 1.0-1.3 | 23.0-27.5 | 0.5-2.5 | 0-1.5 | 0.8-1.2 | ≤0.04 | ≤0.05 |

Special Material Composition

High Manganese Steel: Mn18Cr2 | ||||||

Material | C | Si | Mn | Cr | P | S |

| Tolerance | 1.20-1.35 | ≤1.0 | 16.00-19.00 | 1.50-2.50 | ≤0.07 | ≤0.07 |

| High Chromium Alloy Insert: Cr26Mo0.5 | |||||||

| Material | C | Si | Mn | Cr | P | S | Hardness HRC |

| Tolerance | 2.8-3.0 | ≤1.0 | 0.5-1.1 | 23-28 | ≤1.0 | ≤0.06 | 58-62 |

| Titanium Carbide Insert | |||||

| Material | C | Ti | Mo | Mn | Ni |

| 0.5-0.7 | 46-50 | 0.7-0.9 | 12-15 | 1.8-2.2 | |

| Result | 0.67 | 49.5 | 0.81 | 14.84 | 1.97 |

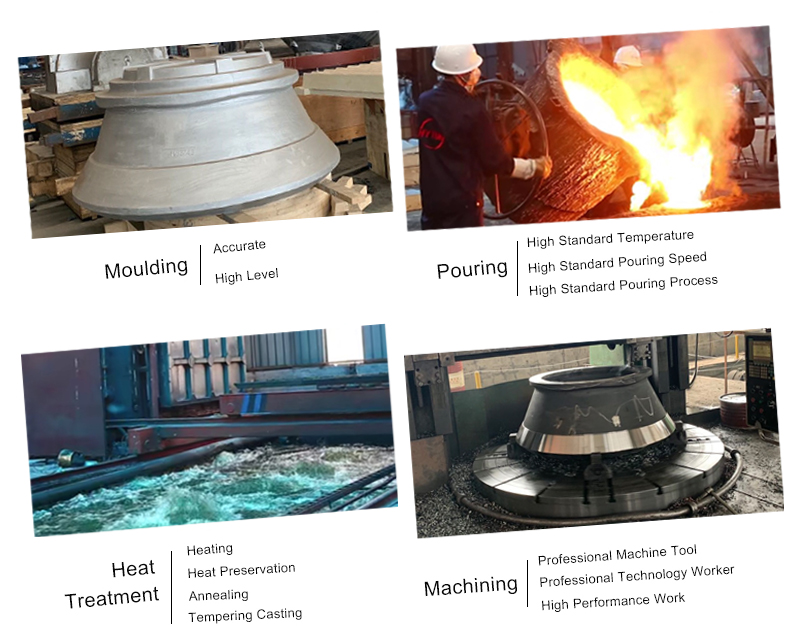

Production Process

Company Profile

Ma'anshan Hyton Heavy Industry Technology Development Co., Ltd. is a leading enterprise in the large-scale engineering machinery wear-resisting casting industry in Anhui Province, Maanshan City. As a new high-tech enterprise professionally manufacturing wear-resisting casting product Which specialized in manufacturing and research of High manganese and high Chrome wear parts. After ten years of rapid development, Hyton has now become a renowned enterprise in China's wear-resisting casting industry; it has become one of the famous supplier of wear parts for crusher and concrete mixer.

Established in June 2004, the company is now undertaking a National Torch Program Project,and five of its patented products have been honored as the "New High-Tech Product" of Anhui Province two of which have been listed into the New Products Program of Anhui Province. The company's wear-resisting casting products have been praised to be the "Famous-brand Products of Anhui Province", the company has been appraised as a "Trustworthy" unit of Anhui Province for many consecutive years. It was selected as one of the first batch of enterprises in Bowang District to be cultivated as the "Little Industrial Giants". In April 2014, Hyton Heavy Industry been selected as the 2nd Top 100 China Foundry Industry Enterprises again, which isanother landmark honor after being recognized as the "Professional, Refined, Special and New"Enterprise in Anhui Province.

Located in the New Material Industrial Park, Bowang High-Tech Zone, Ma'anshan City, the company covers an area of 90 Square kilometer and currently has more than 300 employees. The company is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China, the most advanced sand treatment system in China. With three gas trolley heat treatment furnace and pusher-type furnace full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings

Packing and shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

After goods well packaged, we need only 1 day ship goods to shanghai port, which means that most of the spare parts you bought from Hyton, it will get your port within 45 days all around the world if shipment by sea.

Our Advantages

1) Your inquiry related to our product & price will be rapidly.

2) Well trained & experienced staff are to answer all your inquiries in English of course.

3) Your business relationship with us will be confidential to any third party.

4) One stop purchase service: extensive range of products for qualified offering.

5) We response to client's inquiry within 12 hours.

FAQ

1. Q: What advantages of your products?

A: First, our products are made of high manganese steel material Mn18Cr2, which has high ductility and strength.

Second, our products have High Chromium Alloy Insert inserts, it can improve 30%-200% service life of your products.

Third, we can also provide other insert materials to increase the service life of your products, such as Titanium Carbide Insert, ceramics insert and etc.

Welcome you to contact us to learn more.

2. Q: How long is your lead time?

A: Our lead time is generally 30 days for existing patterns, 45 days for new patterns. Exact time to be finalized on receiving of finalized order.

3. Q: What kind of products do you make?

A: We specialize in mining machinery parts, crusher wear and spare parts, metallurgical equipment spare parts such as jaw plates, concaves, mantles, bowl liners, mill liners, shredder hammers, rolls, and more. They can suit lots of world famous crushing equipment brand suach as: Nordberg, Sandvik, Telsmith, Terex, Symons, Trio, Kleeman, Extec and etc. We also provide various product customization services, you can contact us to discuss more.

4. Q: How do you deal with quality problem?

A: We adhere to "Be honest people create perfect product" development principle since our foundation. Every single product is strictly checked and well packed before delivery. If something goes wrong when you use our products, please send us photos of the wear part and the machine. This will help us to identify where the problem is. If it is a quality problem, we will compensate you and do something correspondingly to avoid the same problem next time. If the problem is caused by misuse,we will provide our technical advice for your reference.