| Availability: | |

|---|---|

| Quantity: | |

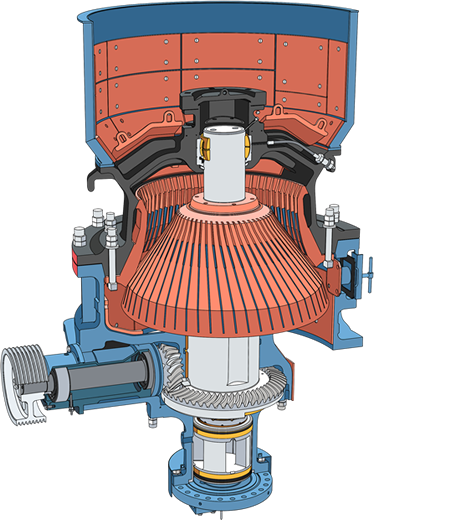

C140

HYTON

84749000

Hyton is one of the most experienced producer supply the one-stop solution for crusher wear parts , our products widely suit most of the famous brand crushing eqquipment in the world , such as : Metso ,Sandvik , Telsmith ,KPI ,JCI Trio ,Terex , Krupp, Symons and Etc .

The Hot crusher model we have supplied the casting wear parts as below :

Metso : HP100 HP200 HP300 HP400 HP500 HP3 HP4 HP5 HP6 HP700 HP800 MP800 MP1000 GP100 GP11F GP11M GP200 GP200S GP220 GP300 GP300S GP330 GP500 GP500S GP550 GP7 C3054 C80 C95 C96 C100 C106 C110 C120 C125 C130 C140 C145 C150 C160 C200 42-65 50-65 54-75 62-75 60-89 NP1110 NP1213 NP1315 NP1415 NP1520 NP1620 NP2023 B6150SE B7150SE B9100SE

SANDVIK: CH420 CH430 CH440 CH660 CH860 CH870 CH890 H2800 H3800 H4800 H6800 H8800 CS420 CS430 CS440 CS660 CJ208CJ209 CJ211 CJ408 CJ409 CJ411 CJ412 CJ413 CJ612 CJ613 CJ815 JM806 JM807 JM907 JM1108 JM1208 JM1211 JM1312 JM1511 JM1513 CG650 CG820 CG840 CG850 CG880 CI121 CI122 CI123 CI124 CI125 CI231CI221 CI222 CI232 CI223 CI233 CI224 CI234 CI225 CI235 CV117 CV128 CV129 CV215 CV216 CV217 CV228 CV229

TELSMITH:T300 T400 T500 T900 TRAC10 38 SBS 44 SBS 52 SBS 57 SBS 68 SBS 44 SBX (300 HP) 52 SBX (400 HP) 57 SBX (500 HP)H2238 H2550 H3244 H3450 J3858 1021 1538 2036 2044 2250 2540 3042 2640 2650 3350 2449 2854 3055

TEREX:TC1000 TC1300 MVP550 CSW1000 CSW1300 CSW1516 JW40 JW42 JW55

TRIO: TC260 TC350 TC450 TC650 TC682 TC685 TC686 TC2TE T900 TC841 TC845 TC848 TC5A TC6A C1030 C1040 C1048 C1251C1252 C2036 C2045 C2436 C3042 C3054 C3254 C3648 C4254 C4763 C6080 CT3254 CT2645 K3124 K3126 K31X04 K31X06 NCT3042

SYMONS: 2Ft ,3Ft ,4Ft,4.25ft ,5.5ft,7ft

The main products of the Wear parts Hyton serviced as below :

Mantle , Bowl Liner ,Concave ,Jaw Plate , Hammer Plate ,Blow Bar, Feed Cone , Cheek Plate , Breaker Plate , Wedges and Etc .

Hyton Casting Equipped with advanced Italian FATA Lost-Foam casting production line and V Process Casting production line, The technical equipment of hyton are at the leading level in the industry, Hyton work in this line more than 15 years, which make ushave strong technical advantages and rich experience in the production of wear-resistant castings. The annual output of wear resistant castings from hyton is more than 20, 000 tons.

1.Why we choose Manganese Casting liner ?

Manganese steel has been used in crushing applications for over 100 years, so it’s easy to take it for granted. It continues to be used because of the remarkable property that makes it ideal for wear liners: the harder you hit it, the harder it gets.

2.How much manganese ?

So the more manganese the better, right? There’s a little more to it than that. It's true that, within a certain range, the higher the manganese content in an alloy, the harder it will be. This simple relation probably explains the popularity of alloys with a high manganese content over the last few decades.However, by increasing the hardness of a wear liner you also increase its brittleness.

A more brittle alloy is more vulnerable to cracking under high impact. An alloy with a slightly lower manganese content (around 13-14%) will be more ductile and durable, and can therefore absorb more hits without cracking. Depending on the application, harder isn’t always better. Alloys with a high manganese content are especially good for crushing abrasive rocks, but for crushing harder rocks you may be better with a lower manganese content that offers greater impact resistance.

Then there is the presence of other elements in the alloy – carbon increases the hardness and wear resistance of the alloy, and chromium helps prevent ‘metal growth’ (where the liner expands and becomes too large for the crusher). Getting the right ratio of these elements relative to manganese is a delicate balance. Too much carbon or chromium affects the atomic structure of an alloy, stopping it from solidifying into an austenitic microstructure – this would make the alloy far weaker and it wouldn’t have the desired work-hardening qualities.

3.What is the famous Materil Hyton Serviced ?

Hyton mainly service the Manganese casting liner like : 13%MN, 18%MN, 22% MN MN13CR2, MN18CR2, MN22CR2 MN13CRMO MN18CRMO MN22CRMO.

4. What kind of Standard Hyton can match ?

US: ASTM A128/A532 AUS: AS2074 H1A/-H1B UK : BS 3100/ BS4844 GE: GX 130 MnCr South Africa: SABS 407 JANPAN : SCMnH11 China : GB/T 5680-2010

A1: Reasonable Price but 100% Quality guarantee is the Core advantage of Hyton , If any parts made in

Hyton have bad quality or short life time , we will pay you same Qty parts free with freight cost .

Q2:Why I can trust you have the good quality as your promise ?

A2: We always ask our customer take 2 or 3 sets liners to test the quality first , this may important for you to choose a new partner , action speak louder than words , in addititon , we sugget all of our customer not pay 100% money before get the inspection report and pictures from Hyton, only after we solve all the questions you may have , you make the balanced-payment process.

Q3: What is your Quality Control Process of the products ?

A3: Hyton have more than 15 years experience works with partners from more than 40 countrys arorund the world, most of the customer from Europe , America , Russia , Australia and etc , so we have compelete quality inspection system, our Quality control plan include the Chemical analysis, Heatment ,Hardness,Microstructure,Visual Inspection, Dimensional Inspection , Packing Inspection .

Q4: If we can be the local dealer of Hyton ?

A4: yes , of course , after you get the standard of the Hyton's Dealer ,Hyton can sign the Dealer Agreement with you , Pls check the details with sales Man of Hyton .